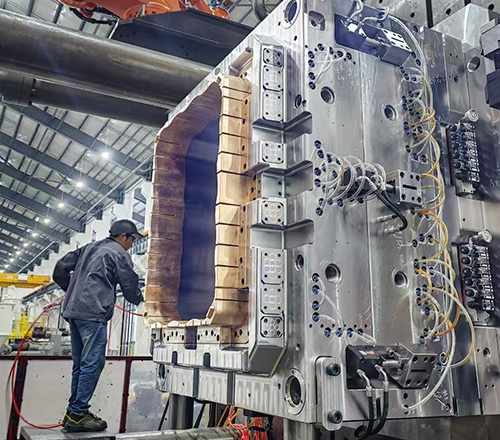

Advanced Mould Manufacturing Capabilities

Focusing on injection molds for more than 20 years, we have a professional team that integrates marketing, projects, research and development, manufacturing, quality control, etc. We adopt two characteristic management systems: Kaihua KMS lean management and Kaihua KMVE value engineering. With the support of high-precision equipment such as Makino from Japan, Fidia from Italy, Demagi from Germany, and KraussMaffei from Germany, we integrate high-quality supply chains and continue to maximize value for our customers.

Makino Graphite Automation

Makino Top Out/Inlaying Automation

Higher capacity/More precise

Faster delivery time/Fewer operators

FANUC MES digitalization

Intended to continuously improve manufacturing time

Central air conditioning fully covered

All equipped with robots, including KM1600T multi-point injection molding machine later in 2022. The picture was taken before 2021

Hydraulic clamping, magnetic clamping, large water supply

First class machinery and equipment

15 sets of German KraussMaffei 1600T three color injection molding machines, including Haitian 4500T and Izumi 3300T injection molding machines High precision three coordinate detection equipment from Sweden's Hexacon and Germany's Wenzel Auxiliary equipment such as robotic arms, ice water machines, water temperature machines, oil temperature machines, hydraulic/magnetic code molds, etc German Schenck balancing machine, American hardness tester, flaw detector and other equipment

Innovative High-efficiency Techniques

We have obtained over 200 patents and provide customers with the best solutions by proficiently mastering and flexibly applying lightweight technologies such as "micro foaming, thin-wall, gas assisted", as well as high-efficiency innovative technologies such as "stacking molds, low-pressure injection molding, and die cutting".

Lightweight

MuCell

Gas Assistance

Thin Wall

Efficiency

Stack Mould

Low Pressure Injection Molding

In-Mold Degate